Services

Development

Product development and engineering consulting with focus on manufacturability and cost control. System-level thinking from concept to production. Deep experience in DFM, supplier alignment, and failure prevention. More than a decade of industry work translating ideas into production-ready hardware.

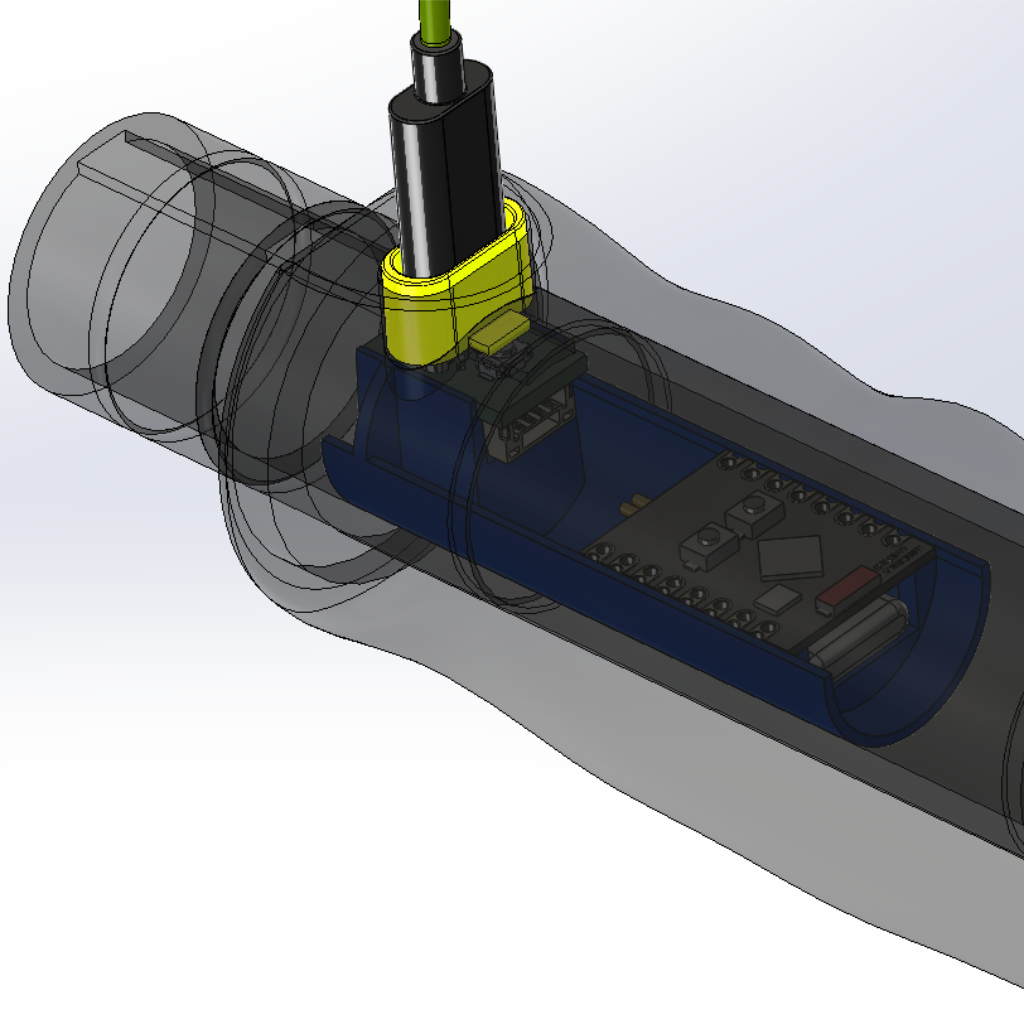

CAD

Mechanical CAD focused on production reality. SolidWorks-based design for injection molding and sheet metal. DFM-driven part design and assembly optimization. Creation of technical drawings, manufacturing data, and high-quality renderings for internal review or customer communication.

Prototyping

Rapid and production-oriented prototyping. SLA and FDM for early validation, CNC machining for functional parts, and sheet metal for enclosure development. Finishing options including painting and UV printing. Prototypes for engineering questions, validation, and presentations to customers or investors.

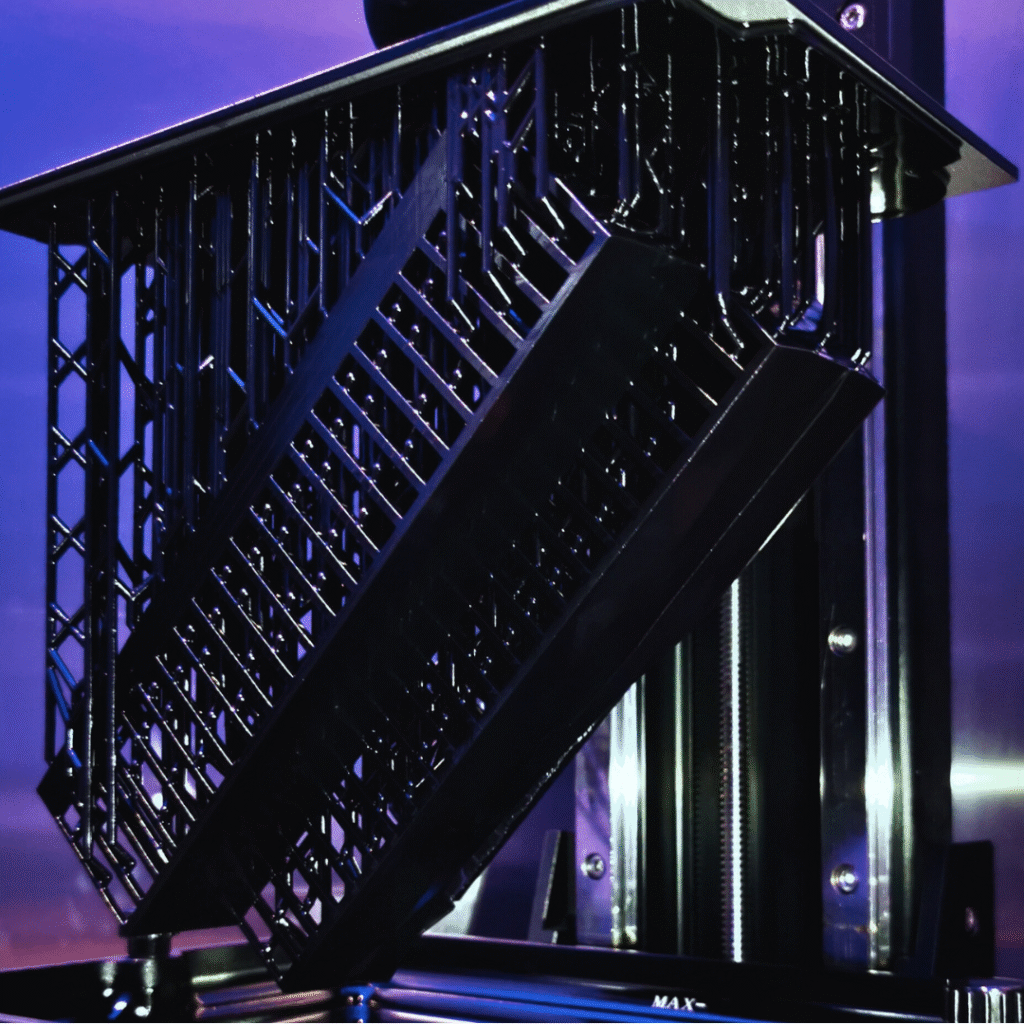

Wave Solder Mask

Custom wave soldering masks manufactured to specification. Designed for reliable soldering and repeatability in series production. Titanium inserts available for high-wear applications or tight, dense THT/SMD placements.

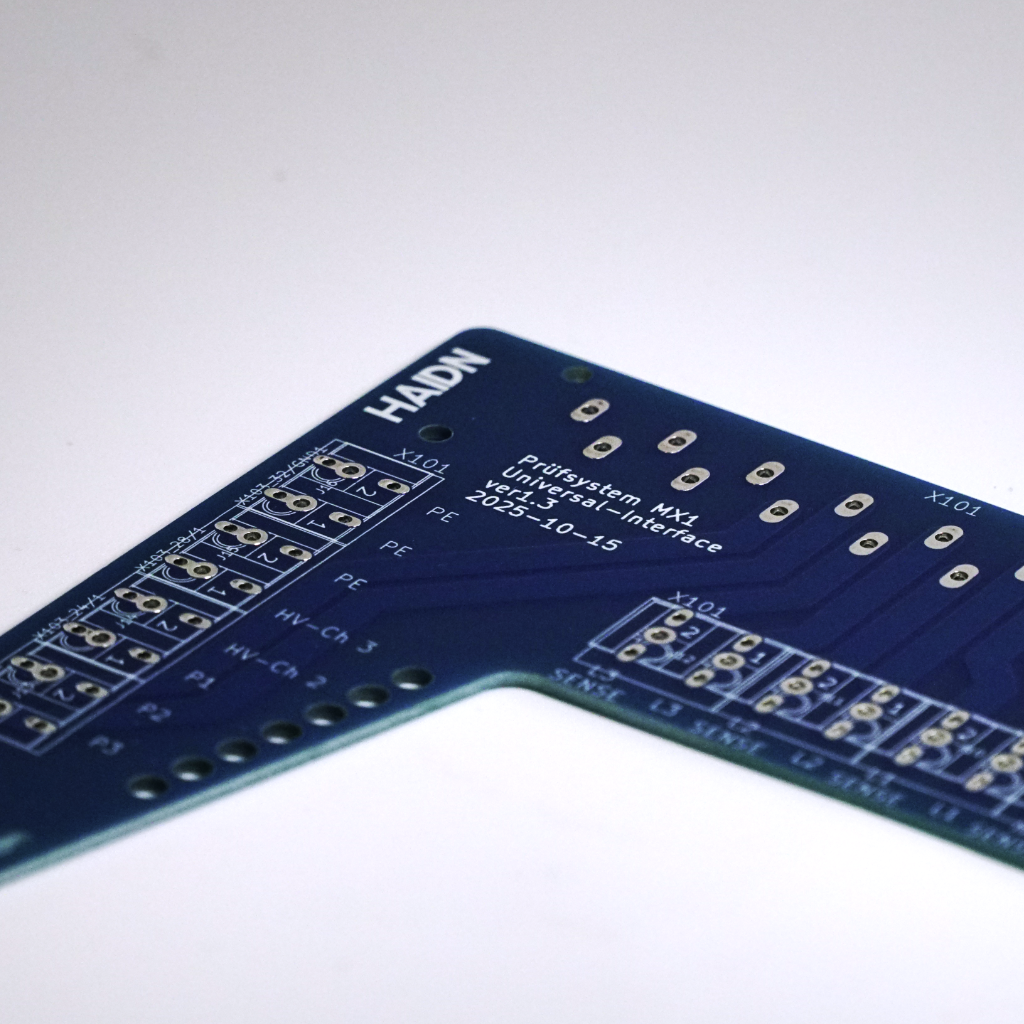

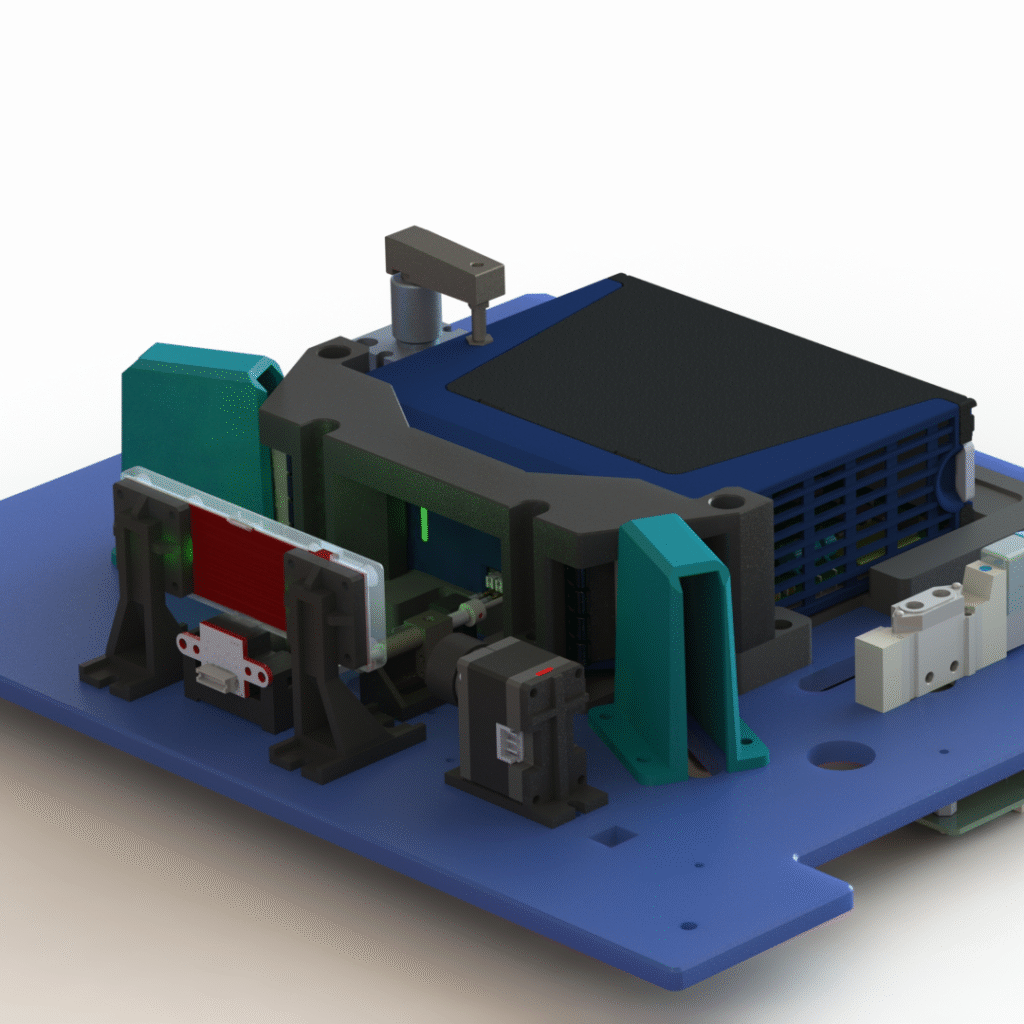

Test Fixtures

Custom test fixtures for production and validation. Needle bed adapters, functional test jigs, programming fixtures, and end-of-line solutions. Integration of machine vision for LED or model detection, servo actuators for potentiometers and switches, and automation-ready designs.

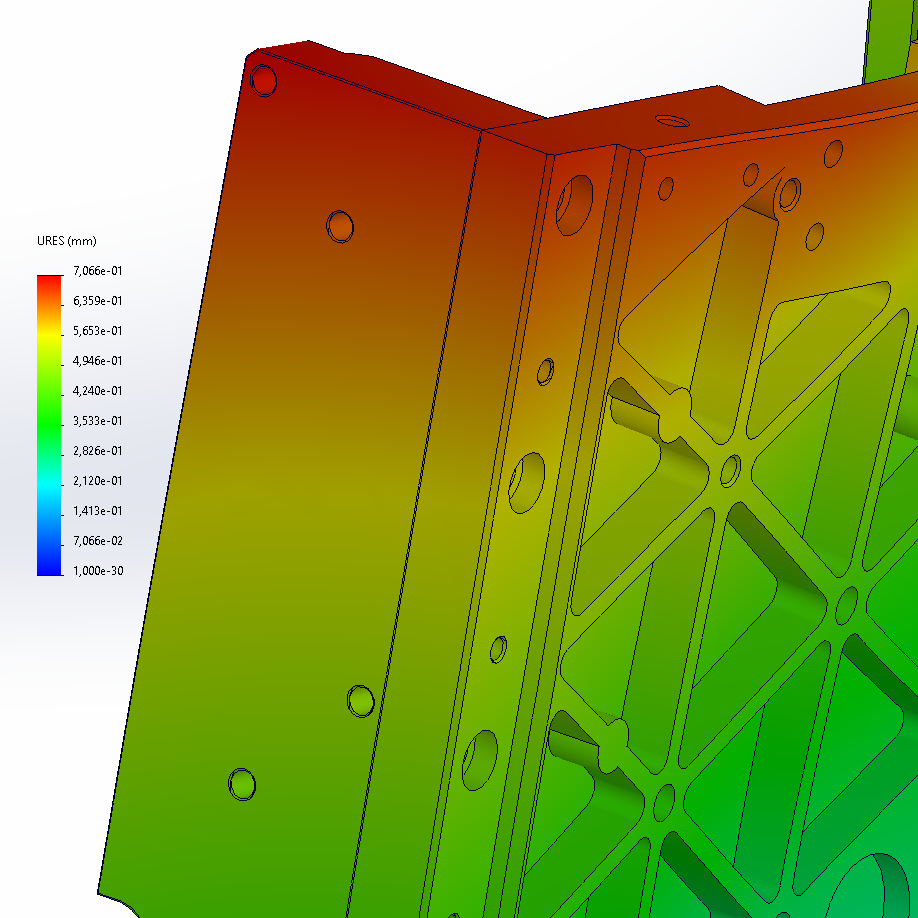

FEM Analysis

Structural simulation to reduce risk before tooling. Strain and stress analysis, deformation under load, material comparison, and design iteration based on results. FEM used as a decision tool to improve durability, safety, and cost efficiency.